- Joined

- Jul 14, 2020

- Threads

- 125

- Messages

- 6,164

- Reaction score

- 7,037

- Location

- California

- Vehicle(s)

- Jeep Wrangler JKUR

- Your Bronco Model

- Wildtrak

Well regardless of how this actually happened, how many times have we come off a ledge or a rock and smack the trailer hitch? I mean most people treat the hitch sort of as a "rear rock slider"

I was thinking of ordering that hitch slide to make sure that that gets hit before anything else including my bumper and spare tire... Now I don't know.

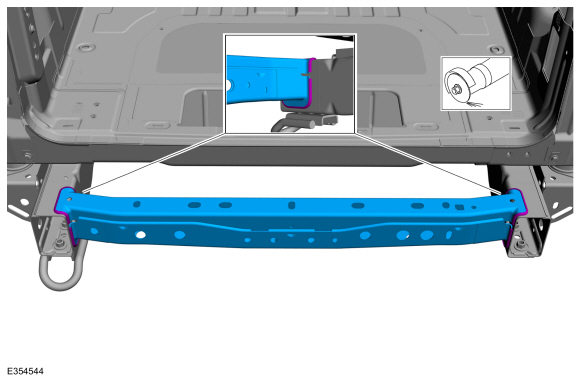

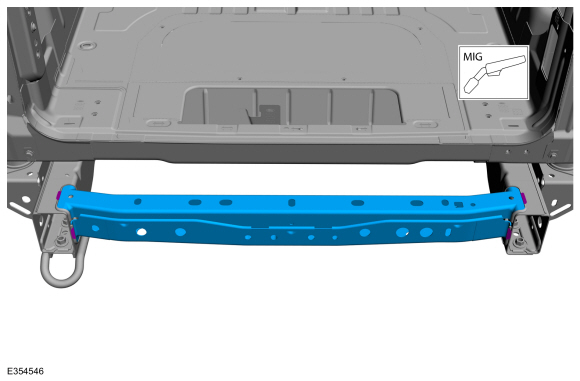

Maybe having some reinforcement metal added to that middle brace to keep it from twisting or bending.

I mean I get the crumple zone concept.. this kind of seems like the tie rod problem... I really looking for a weak point where it actually should be stronger than the norm.

I was thinking of ordering that hitch slide to make sure that that gets hit before anything else including my bumper and spare tire... Now I don't know.

Maybe having some reinforcement metal added to that middle brace to keep it from twisting or bending.

I mean I get the crumple zone concept.. this kind of seems like the tie rod problem... I really looking for a weak point where it actually should be stronger than the norm.

Sponsored